SPECIALIZED SERVICES

FOR OVER 40 YEARS, ITALSTEEL HAS BEEN COMMITTED TO PROVIDING QUALITY STEEL FABRICATION AND INSTALLATION PROJECTS THROUGHOUT WESTERN AUSTRALIA.

Our experienced team offer a complete service from Detailing Drawings to Fabrication and Erection, with professional Project Management assistance available when required.

WE UNDERSTAND THAT QUALITY SHOP DRAWINGS ARE THE FOUNDATION OF EVERY SUCCESSFUL STRUCTURE.

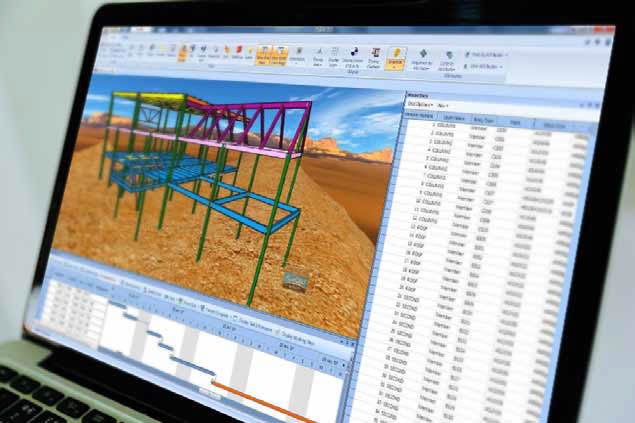

Over the last 40+ years, we have built relationships with Perth’s best shop detailers in order to ensure our clients access to the highest quality drawings available. When requested, Italseel will engage a qualified drafting team to provide complete detail drawings and documentation for large and small structural steel projects – with concrete panel drawings available on request. Our subcontractors will capture and create working drawings and build a complete 3D model from your structural drawings. From these drawings, they will then generate NC and DXF Files along with a detailed bill of materials report, categorised into different sectors of necessary products; Nuts, Bolts and Treatments, along with all Specialty Items to ensure supply clarity pre-build.

A detailed 3D viewing model will be generated to allow the client to view the ‘finished product’ and see their completed project from all angles. This is crucial to ensure a smoothly-run project and to give all parties a clear understanding and visual of how the structure is put together down to the most complex components. All Detailing Drawings will meet the highest BIM (Building Information Modelling) requirements to allow for smooth future updates or improvements to the structure.

Italsteel Detailing Drawings Include:

- NC Files

- Detailed bill of materials

- DXF Files

- Meet highest BMI requirements

- 3D viewing model

Throughout our 40+ years of steel fabrication, we have refined our processes, improved our methods and developed industry-leading expertise in every area of fabrication. This allows us to stand behind the quality of every item which leaves our workshop.

Structural Steel Fabrication

Our workshop is fitted with the latest technology in structural steel processing and is equipped with all machinery needed – such as our Shear Stud Machine and Reinforcing Bar Bending Machine – to supply fabrication for the most extensive projects. From processing to assembly and fabrication of the members, we implement quality and safety practices beyond the industry standards of accreditation. Everyone in our team who fabricates a member is required to sign off on their part of the work for total traceability.

After fabrication, each member is inspected by our full-time, inhouse checker. Then, once the welds are complete it is examined again for quality – with all steel being straightened prior to leaving our yard from heat distortion. When required, we employ external accredited organisations for ultrasonic and mag particle testing to assure our clients all welds are compliant.

These are just some of the methods we use to maintain our award-winning position at the forefront of the steel fabrication industry.

Plate Steel Fabrication

Our Plate Steel Fabrication capabilities allow us to service the mining industry by fabricating hoppers or tanks to suit any requirements.

Whether for practical purposes, aesthetic or both, Italsteel can provide any form of surface treatment to suit client specifications.

Paint Treatments – such as powder treatment, protective treatments (to prevent corrosion or protect against fire) or topcoats – can be applied to complete your steel components. On request, additional quality checks can also be provided with documentation supplied to outline the total scope of works.

Galvanising Treatments create a series of highly abrasion-resistant zinc-iron alloy layers for tougher steel, along with providing it’s silver/grey colouring. Quality documentation can be provided on request, in addition to our standard practice of through internal checks, with all material returning to our workshop for a full inspection to check for straightness, pressed edges and vented exposure, along with all holes being filled and treated. Not a single item leaves our yard unless it is indisputably straight.

For more than four decades, we have provided not just quality to our customers, but a consistently on-time service – so you can trust we will hold up our end to get your project completed on schedule.

Part of our ability to provide this is our Transport service capability, delivering your steel products to site with our fleet of trucks and experienced drivers.

Our Transport Offering:

- Two Scania Prime Mover Road Trains

- Four Extendable Trailers

- Fully accredited for oversize loads

- Detailed logs of all drivers and service history

- Safe, on-time delivery

- Up-to-date accreditation

- Escorts provided to meet all criteria

- Delivery across Western Australia

- ‘Just-in-time’ delivery loading

Our team know all about the requirements for smooth delivery of materials, leading to faster and more efficient builds. Our fleet can be specifically loaded for ‘just-in-time’ delivery to meet specific project timeframes and site constraints.

Erecting quality steel structures requires expertise gained from thousands of successful projects.

Over our 40 years of complex construction and engineering projects, we have built relationships with the best in the business and engage the top independent riggers in the state for our client projects.

With our in-depth knowledge of the requirements of any steel structure installation, we will enlist a team of fully qualified and accredited riggers who approach each project with their own experience as well as undergoing VOC induction training to equip them for each specific install.

As safety is a priority when erecting steel structures, we only work with riggers who employ full health and safety documentation, SWMS, to document their process for identifying and controlling health and safety hazards and risks. This allows us to fully analyse each activity for hazards and potential incidents to minimise the risks in undertaking your installation. We will also provide plant and equipment registers for every project.

Every erection is overseen by our experienced Managers to ensure the successful outcome of your project.

In every area of our service, Italsteel is committed to quality.

We hold the industry standards of accreditation as our minimum when it comes to quality and safety practices and have spent our 40-years in business developing and maintaining our own additional practices above and beyond what is required.

We take our Quality Assurance very seriously and are ISO 9001, 14001, 45001, SSA L2B and SCA CC3 accredited. We conduct thorough and documented checks of each product we produce to assure our clients the steel is of the highest quality and the process has been executed with attention to detail and to industry standard.

This service provides the platform for precision programming of processing, fabrication, assembly and quality deliverables.

Our Quality Assurance Process:

- Plans are submitted

- Quality Management Plan completed

- Inhouse checker at each stage of the manufacture process

- Accredited fabricators and riggers

- Visual Checks

- Quality docs on fasteners

- Installation certification from riggers (to AS Standard)

- Inspection Test Plans (ITP)

- Mag Particle Testing

- Qualified Management supervision

Italsteel completes all works to AS 1552, along with each client’s project-specific quality specifications.